Imaging the space observatories of the future

Imaging the space observatories of the future

Becky Bosco, Senior Director of Corporate Communications, Optica

The 2023 Optical Fabrication and Testing Topical Meeting (OF&T) met in Québec City, Canada, as a part of Optica’s Design and Fabrication Congress to convene on new concepts and emerging applications in optics manufacturing and metrology. Hot topics of the fabrication of optics by lasers, additive manufacturing of optical components, molding of micro-optics, deterministic manufacturing of aspheric/conformal/freeform optics, advanced metrology systems, and direct slope/curvature measurement, fabrication of optics from novel materials, efficient manufacturing, and testing of large optics.

Dr. Jonathan Arenberg is Chief Engineer for Space Science Missions at Northrop Grumman Aerospace Systems in Redondo Beach, CA. Arenberg took the plenary stage to share the pioneering design of NASA’s James Webb Space Telescope (JWST).

Arenburg explained, “The mission of JWST is to discover things about the universe that we never knew before today. It fundamentally alters our understanding of the universe.” Over 20 years of research and engineering and 100 million hours of people’s lives were spent ensuring the success of JWST. Today, JWST is orbiting Lagrange Point 2 (L2), approximately a million miles away from Earth, peering back in time that shows us how the universe looked in its earliest days. “Getting to this point was no easy feat,” said Arenburg. “JWST is orbiting farther than any manned spacecraft has ever traveled – and engineers had only one chance to get it right.”

Northrup Gumman’s efforts

The Northrup Grumman team looked at a blank piece of paper and developed its plan with a shared diversity of thought and experiences around the table. “There isn’t a company in the world that could have done this alone,” said Arenberg. Before the team could build the most complex telescope ever, they had to invent technologies that had never existed before. For many Northrop Grumman employees, the opportunity to work on Webb was the opening for boundless opportunity. From a new element on the Periodic Table and embracing digital transformation to creating zero gravity here on Earth, Northrop Grumman employees developed something that the entire universe should celebrate.”

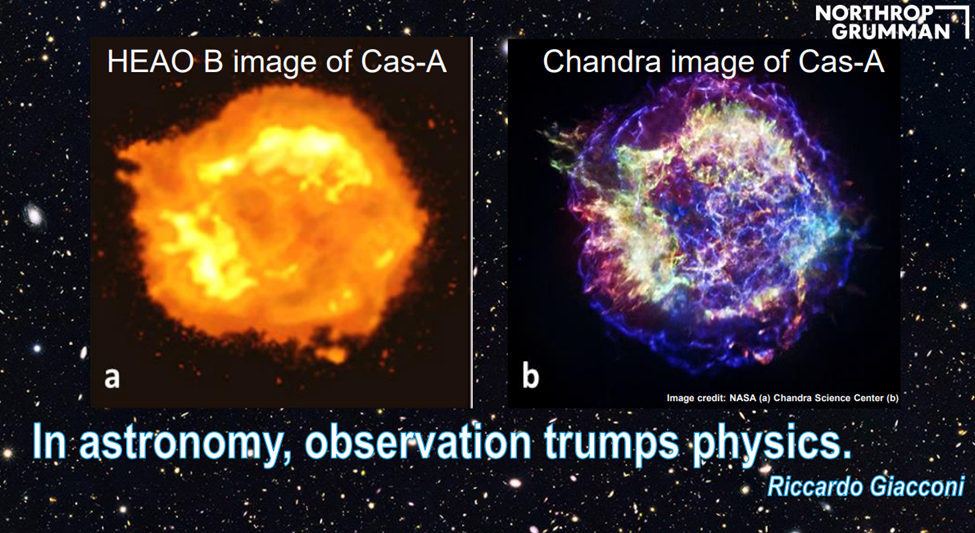

In astronomy, observation trumps physics

Arenberg highlighted:

- Observation requires hardware; make the best use of it

- Photons are precious and valuable; don’t waste them

- Building hardware takes time and money; time and money are finite

- Astronomy is technology limited; the optics need continued improvement

Fundamental challenge: Manufacturing the optics for astronomy

Arenberg then looked to the Pathways to Discovery in Astronomy and Astrophysics for the 2020s, identifying the most compelling science goals and presenting an ambitious program of ground- and space-based activities for future investment. The report recommends critical near-term actions to support the foundations of the profession as well as the technologies and tools needed to carry out the science.

LUVOIR, the next generation to Hubble, is a general-purpose astrophysics observatory capable of performing observations from ultraviolet to infrared with imaging and spectroscopic instruments. The LUVOIR mission would enable great leaps forward in a broad range of science, from the epoch of reionization, through galaxy formation and evolution, star and planet formation, to solar system remote sensing. LUVOIR also has the major goal of characterizing a wide range of exoplanets, including those that might be habitable - or even inhabited.

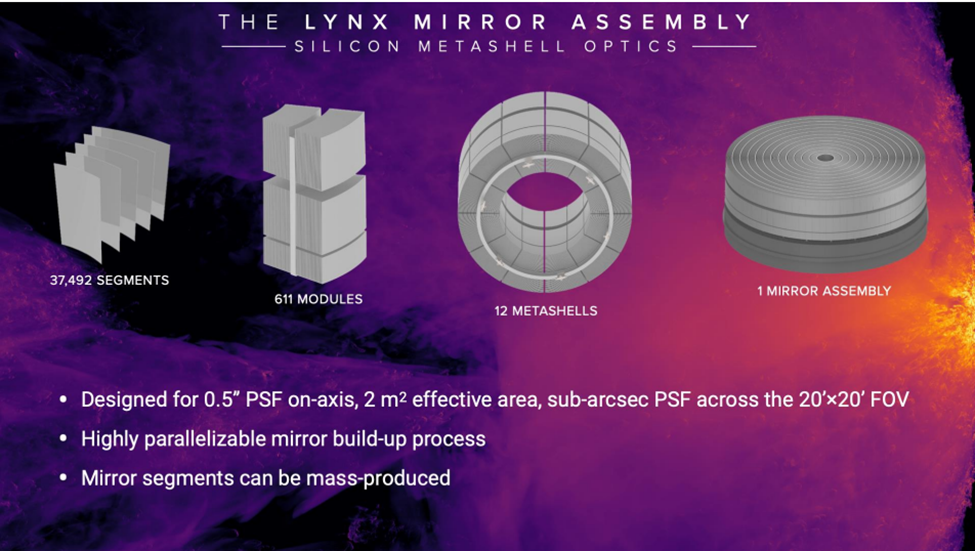

LYNX, a grazing incidence x-ray telescope with 2 m2 collecting area, will provide insight into the otherwise invisible universe – from supermassive black holes in the first galaxies, the processes that drive galaxy formation and evolution, and the high-energy aspects of stellar evolution.

Nautilus: New technology unlocking new science

Nautilus Array is a concept for a large collecting array (1950 m2) for space. In collaboration with the University of Arizona, Northrup Grumman developed designed a compact mode lens sized from 589 nm to 727 nm. The lens combined refractive and diffractive optics, thus achieving the first glass-molded MODE lens. The seminal MODE lens is molded. Optimization of manufacturing is an explicit area of investigation. Arenberg explained, “Optics manufacturing is the engine driving astronomical advancements. Ongoing improvements in manufacturing technologies will underwrite the continued advancement of astronomy for the next 400 years.”

Reflection on the JWST experience

Arenberg reflected, “I come from a background where I was never exposed to engineering. Coming out of college and knowing I get to work on something as amazing as James Webb telescope is something I'm very proud of every time. It causes you to think about everything you're doing here on earth when you're testing it you know it has to work when it's in space. I love it when someone puts something on the table and says this is impossible and we get the opportunity to figure out how to make it happen. With JWST, there wasn’t a road map out there, and we were starting from scratch. This is probably the biggest thing that I have done in my life and an experience that I am unlikely to have again. I treasure it knowing JWST will advance human knowledge.”

Read more: Jonathan W Arenberg and Lynn Allen, “A Report on the Feasibility of Manufacturing the Lynx X-ray Mirror Assembly,” https://www.dropbox.com/s/1vm23v95vu n7u62/XMA_Industry_Report_PUBLIC.p df?dl=0