That changes everything: How lasers are transforming the economics of industrial production

Optica Blog

That changes everything: How lasers are transforming the economics of industrial production

Dr. Becky Bosco, APR - Senior Director of Corporate Communications, Optica

Fiber lasers are capturing an increasing fraction of the nearly US$80 billion global tool market. Vice President of Fiber Laser Technology at nLIGHT, Dahv Kliner's plenary presentation at Optica’s Laser Congress highlighted how the laser is transforming the economics of industrial production. The industry has changed since nLIGHT entered the fiber laser market in 2014, and Kliner explained key growth drivers.

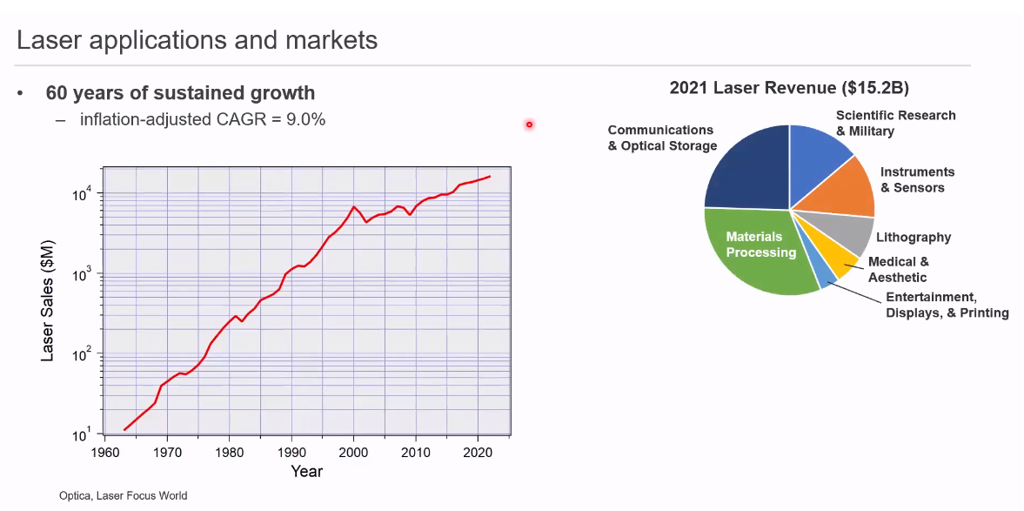

The laser market has had nearly 60 years of uninterrupted growth. In 1963, there were 11 million dollars of lasers sold, and in 2022 the market is above 16 billion dollars. With inflation, this corresponds to a compound annual growth rate of 9 percent. The single largest market is materials processing. From there, we break the market into marking and engraving, micro-processing, and macro-processing. The largest segment, macro-processing, employs kilowatt-class lasers and compromises approximately 20% of the entire global laser market.

So where are all these kilowatt-class lasers going? They primarily go into industrial machine tools, which is an 80 billion dollars annual market. Laser-based machine tools have grown into a 20 billion-dollar industry in the last decade. What's been driving that growth – is fiber lasers.

In 2005, 800 million dollars of lasers were sold into macro-processing, most CO2 lasers. Since then, sales have grown by nearly four to nearly three billion dollars. The growth can be attributed mainly to sales of fiber lasers, which have well over 50% market share. From there, the market is segmented into solid-state and direct-detect lasers. Today, sales of CO2 lasers are nearly a negligible contribution to the market.

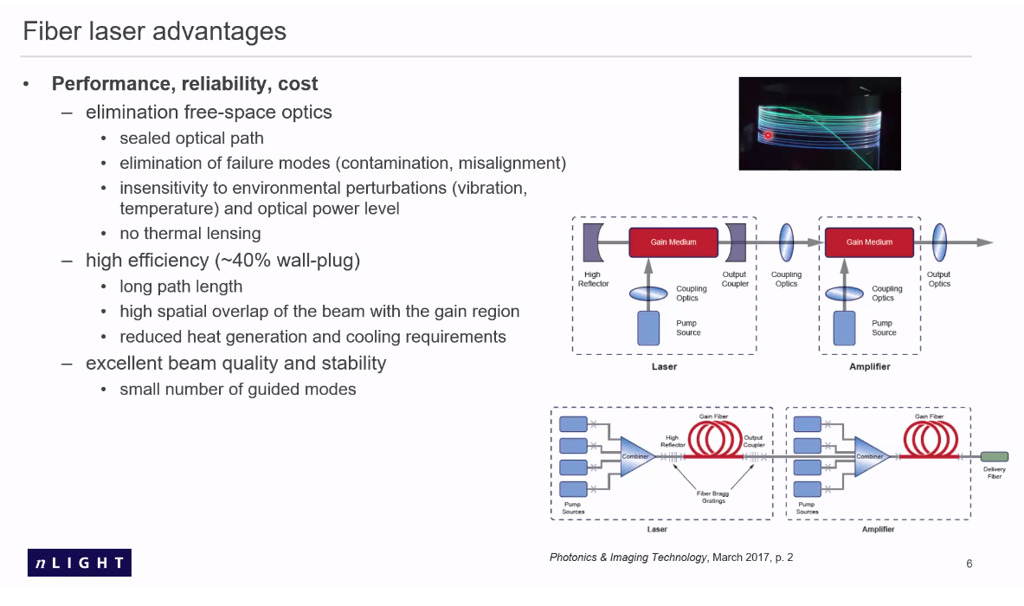

Why have fiber lasers been able to drive multi-billion-dollar growth in machine tools? Fiber lasers offer several unique advantages in terms of performance, reliability, and cost. A key benefit is derived from the elimination of free space optics. The fiber lasers also have the highest efficiency, typically running about 40% wall-plug. High efficiency is possible over long lengths of fiber because of the high spatial overlap of the laser beam with the gain region resulting from the guiding properties of the fiber, which essentially shuts off diffraction. This high efficiency means not just lower power consumption but also the reduction of waste heat generation and the reduction of cooling requirements, which are particularly significant at higher power. The fiber provides very stable and high beam quality, largely defined by the guided modes of the fiber. Maintenance costs are low because routine service is not needed, and the elimination of failure modes associated with free-space optics significantly reduces unplanned maintenance. And finally, fiber lasers are naturally set up for fiber delivery to the workpiece. No other laser technology offers this combination of benefits, leading to displaced legacy technologies and new fabrication capabilities.

The Differentiator – Beam Shaping

It's been known for years, since the CO2 laser days, that the materials processing performance depends on the laser beam, size, shape, divergence, and various application-specific optimized beam shapes have been identified, including Gaussians, flat-tops, ring beams, etc. The beam shape is so important because it controls heat deposition into the workpiece, which is critical for controlling the feature size, maximizing productivity, and minimizing deleterious effects.

Most lasers have fixed beam characteristics, so various approaches have been developed to vary the beam. They typically involve manually changeable or motorizing free-space optics downstream from the laser. Fiber couplers can also be used to change the launch conditions into the fiber, or fiber switches can be used to switch the beam between two or more outputs with different characteristics. These approaches have demonstrated the utility and the value of being able to tune the beam and optimize its shape, but they add significant complexity or cost and/or degrade tool performance or reliability. As a result, most tools still employ a fixed beam shape and suffer from non-optimized performance.

The nLIGHT team developed an all-fiber technology known as Corona™ that enables rapid tuning of the beam characteristics directly from the fiber laser. With the Corona platform, the switching is fast – over full range in less than 30 milliseconds, which means real-time optimization of each process step. The technology is highly reliable, with accelerated life tests with more than 20 million beam changes showing no change in performance.

Corona technology is the basis of several fiber laser products. nLIGHT introduced the first multi-mode design known as CFX in 2018. The laser beam diameter went from 100 microns to 350 microns, a dynamic range of ten times in beam area, and provides various flat-top and ring-shaped beams. CFX is currently available up to 20 kilowatts. This product eliminated the last advantage of CO2 lasers over fiber lasers in the largest industrial market of metal cutting. Specifically, CFX provides excellent edge quality for O2 cutting of thick mild steel while also enabling high cutting speeds for N2 cutting of thin materials (the traditional advantage of fiber lasers).

In 2020, nLIGHT introduced a single-mode design known as AFX. AFX has a standard 14-micron mode field diameter for the single-mode core, and a 40-micron ring surrounds it. With this design, the beam shape can go from a Gaussian to various saddle and ring shapes by varying the partitioning of the beam between the two guiding regions.

Applications in laser welding

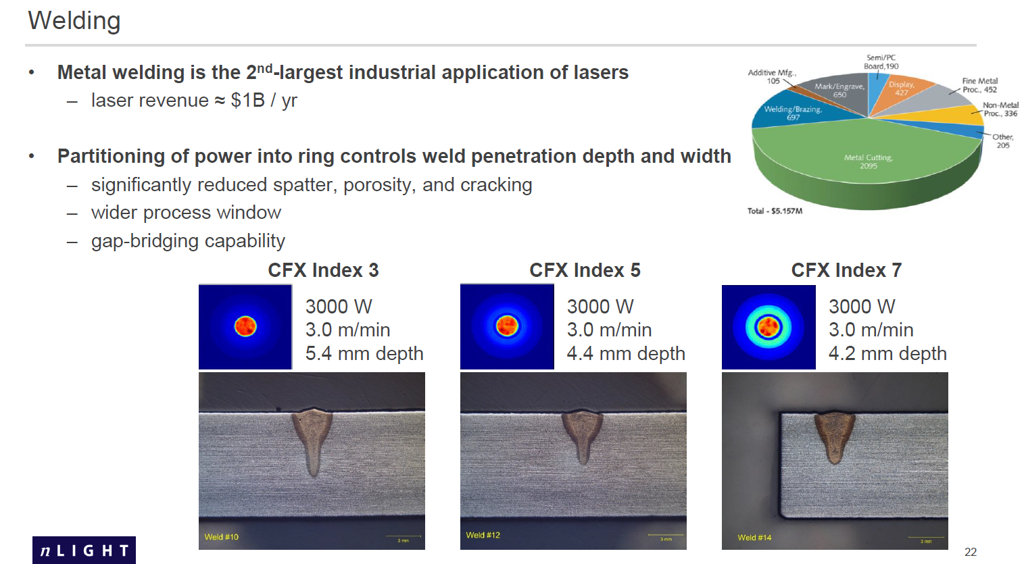

In laser welding, changing the beam shape allows you to control the weld profile and penetration depth. These are three bead-on-plate welds at the same power level, speed, and different beam shapes. Spatter is a common problem in keyhole welding. The spatter particles can contaminate the finished part, which thus requires post-processing, and, if not successfully removed, can create latent failures. The particles can also contaminate the surrounding tooling -- fixtures, shielding nozzles, and clamps. The spatter increases the need for consumables as well as downtime for maintenance.

The beam shapes of nLIGHT’s CFX laser greatly reduces spatter. By partitioning some of the laser power into a halo surrounding the high-intensity central beam, the top of the keyhole is opened up, preventing it from collapsing. This beam shape provides higher productivity in two ways – it allows increase of laser power (speed) without excessive spatter and reduction of post-processing steps.

Future impact of additive manufacturing

Additive manufacturing (AM) provides previously unimaginable production capabilities, and AM is the most important emerging market for lasers. Laser powder-bed fusion (L-PBF), in particular, offers high part quality, fine feature size, and a wide choice of materials. In the L-PBF process, an object is built one layer at a time by fusing a metal powder using a laser. In contrast, subtractive manufacturing produces an object by cutting away at a solid block of material until the final product is complete. The slow build rate of L-PBF leads to a high part cost, which has prevented widespread adoption of the technology for series (high-volume) production. AFX directly addresses this problem by increasing the L-PBF build rate by 2x – 8x while maintaining excellent material quality and a large process window for a wide range of metals (including titanium, aluminum, stainless steel, and nickel superalloys). AFX’s optimized beam shapes enable production of fine features (using the single-mode beam setting) and provide high build rates for bulk features (using saddle- and ring-beams) all using the same laser source. Kliner showed a case study of an aluminum manifold whose cost was reduced by nearly 3x using AFX instead of a standard single-mode laser, which represents a breakthrough in the economics of additively manufactured parts. Furthermore, AFX provides control of the local material properties via control of the microstructure, opening a new dimension for AM. Kliner showed a real-world example of turbine blades manufactured via L-PBF in which the material properties were graded along the blade using different beam shapes.

What is the future of the fiber laser?

Kliner explored the analogy between electronics, which was the defining technology of the 20th century, and photonics, which will be the defining technology of the 21st century. In the first half of the 20th century, electronics was dominated by vacuum tubes. The invention of the transistor in 1947 displaced the vacuum tube and, more importantly, enabled development of integrated circuits (ICs) with multiple functions incorporated into a single, solid-state device. Similarly, macro-processing was originally dominated by the CO2 laser (analogous to the vacuum tube), which has been largely replaced by solid-state laser technologies (analogous to the transistor). But what is the analogy to the transition from individual transistors to ICs? Kliner showed that the fiber laser uniquely offers the potential of incorporating multiple functions into the monolithic fiber platform, a possibility that is not offered by free-space technologies. Corona fiber lasers are an example of such all-fiber functionality, and Kliner provided several other examples of previous and possible future fiber-based advances. He also showed an analogy to Moore’s Law for the price of semiconductor lasers, which are a key component of fiber lasers. Finally, Kliner recalled the Arthur C. Clarke quote that, “any sufficiently advanced technology is indistinguishable from magic.” Although fiber lasers have dominated growth in laser-based materials processing for many years, some of the most exciting discoveries are yet to be made, and “more magic is yet to come.”

About nLIGHT

nLIGHT, Inc. is a leading provider of high-power semiconductor and fiber lasers for industrial, microfabrication, aerospace, and defense applications. Our lasers are changing not only the way things are made but also the things that can be made. Headquartered in Camas, Washington, nLIGHT employs over 1,200 people with operations in the U.S., China, Finland, Korea and Italy. For more information, please visit www.nlight.net.